Capacity 5-8 Per Day Paperboard Machine

- Raw material:Waste paper, waste paper pulp, paper sludge etc

- Specifications:1300mm×1000mm, 1400mmx1000mm, 1500mmx1000mm

- Capacity:5-8t/d

- Host power:5.5kw

- Thick of paper:Can debugging

We are here to help:Easy ways to get the answers you need.

- Culture paper machine

-

- 2400mm Type Fourdrinier Multi-Dryer Newspaper Machine

- 2800mm Daily Capacity 40 Tons Fourdriner Culture Paper Machine

- 1575 Fourdrinier Cultural Paper Machine

- 1092 Type Capacity 3-4tons Writing Paper Machine

- 6-8tons culture paper machine

- 1092mm Fourdrinier Paper Making Machine

- 1092 Type Capacity 5tons Culture Paper Machine

- 787mm Type Culture Paper Machine

- 1575mm type culture paper making machine

- Specialty paper machine

-

- 1600A Model Kraft Paper Slitting Machine

- 1760mm Multi-Dryer Five Cylinder Mould Grey Cardboard Machine

- 1092mm Multi-Dryer Five Cylinder Mould Grey Cardboard Machine

- 2100mm Multi-Dryer Five Cylinder Mould Paperboard Machine

- 4 Heads CNC Spiral Paper Tube Machine

- 2 Heads CNC Spiral Paper Tube Machine

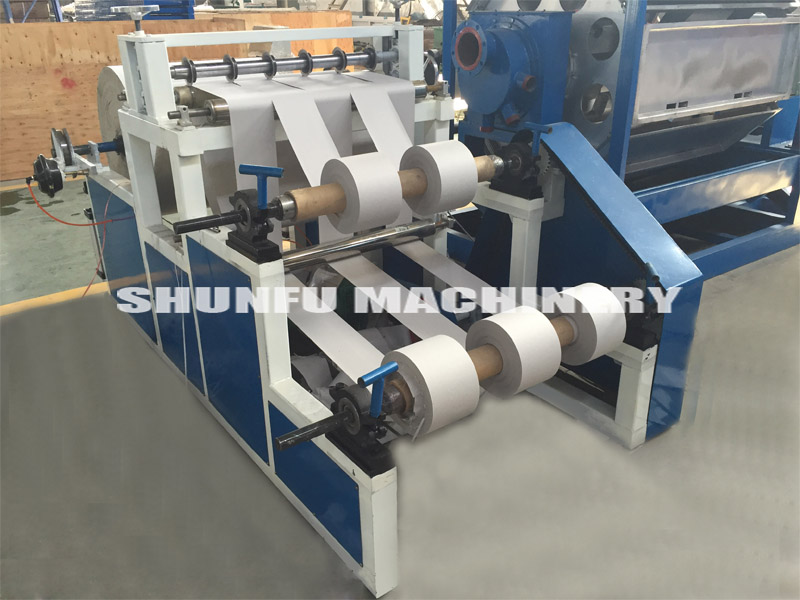

- Capacity 5-8 Per Day Paperboard Machine

HOT PRODUCT

Describe

◆ Technical Parameter

◆ Use Of The Finished Product

Chemical additives packaging box, packaging box lining board, clothing packing box , arts and crafts packaging box, ceramic products packaging box, decorative panels and various types of thread-bound book cover and the outer packaging.

◆ Technological Process

Raw material → Hydrapulper → Vibrating sieve → Horizontal mixer(crude pulp tank) → Pulp pump→ Refiner → Horizontal

mixer(ajust pulp tank) → Pulp pump → Centrifugal screen machine → Horizontal mixer(finished pulp tank) → Pulp

pump→ Steady pulp box → Enter cylinder mould box→ Forming paperboard → Enter hot pressure machine to drying

| Raw material | Waste paper, waste paper pulp, paper sludge etc |

| Specifications | 1300mm×1000mm,1400mx1000mm, 1500mmx1000mm |

| Speed |

5~8m/min |

| Capacity | 5-8t/d |

| Host power | 5.5kw |

| Thick of paper | Can debugging |

| Consistency of pulp | 0.8~1% |

| Appearance size | 9000mm×2500mm×2000mm |

◆ Use Of The Finished Product

Chemical additives packaging box, packaging box lining board, clothing packing box , arts and crafts packaging box, ceramic products packaging box, decorative panels and various types of thread-bound book cover and the outer packaging.

◆ Technological Process

Raw material → Hydrapulper → Vibrating sieve → Horizontal mixer(crude pulp tank) → Pulp pump→ Refiner → Horizontal

mixer(ajust pulp tank) → Pulp pump → Centrifugal screen machine → Horizontal mixer(finished pulp tank) → Pulp

pump→ Steady pulp box → Enter cylinder mould box→ Forming paperboard → Enter hot pressure machine to drying

inquiry

Please fill in your procurement needs and contact information

English

English русский

русский  عربي

عربي  中文

中文