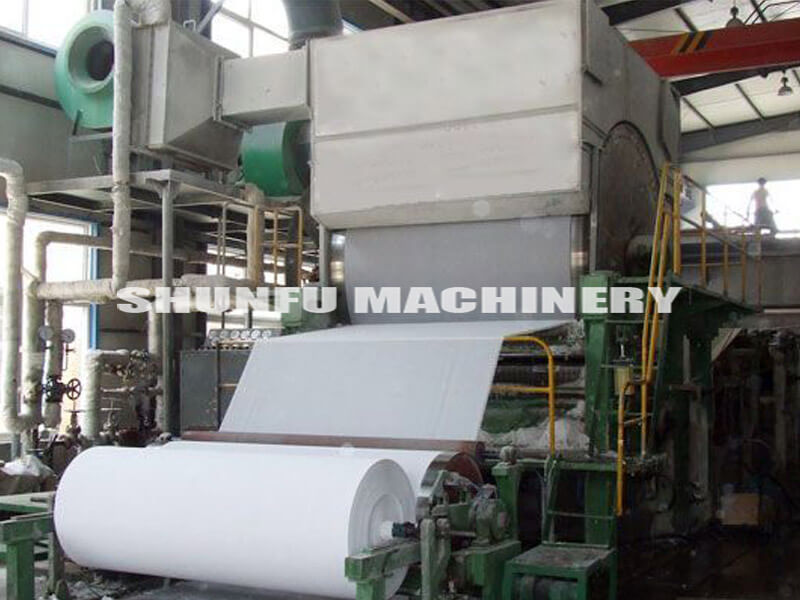

1092 Type Capacity 5tons Culture Paper Machine

- Raw material:Straw

- Output paper:Cultural paper

- Net paper width:1200mm

- Paper weight:45-80g/㎡

- Capacity:5T/D

We are here to help:Easy ways to get the answers you need.

- Culture paper machine

-

- 2400mm Type Fourdrinier Multi-Dryer Newspaper Machine

- 2800mm Daily Capacity 40 Tons Fourdriner Culture Paper Machine

- 1575 Fourdrinier Cultural Paper Machine

- 1092 Type Capacity 3-4tons Writing Paper Machine

- 6-8tons culture paper machine

- 1092mm Fourdrinier Paper Making Machine

- 1092 Type Capacity 5tons Culture Paper Machine

- 787mm Type Culture Paper Machine

- 1575mm type culture paper making machine

- Specialty paper machine

-

- 1600A Model Kraft Paper Slitting Machine

- 1760mm Multi-Dryer Five Cylinder Mould Grey Cardboard Machine

- 1092mm Multi-Dryer Five Cylinder Mould Grey Cardboard Machine

- 2100mm Multi-Dryer Five Cylinder Mould Paperboard Machine

- 4 Heads CNC Spiral Paper Tube Machine

- 2 Heads CNC Spiral Paper Tube Machine

- Capacity 5-8 Per Day Paperboard Machine

HOT PRODUCT

Describe

◆ Technical Parameter

◆ The Main Structure

A. Cylinder part: TwoΦ1250mm×1450mm cylinder moulds, TwoΦ350mm×1500mm couch rolls, Rubber hardness HSD38℃ ±2, OneΦ300×1500 back roll, Rubber hardness HSD 38℃ ±2

B. Compression part: One Φ450mm×1450mm stone roll, One Φ400mm×1450mm rubber roll, Rubber hardness HSD 90℃±2, Pneumatic loaded device

C. Dryer part: Φ2000mm×1450mm dryer 1set, Φ1500mm×1450mm dryer 1set, Φ400mm×1450mm touch roll 1set, Rubber hardness HSD 90℃±2

D. Calander part: Φ2000mm×1450mm dryer 1set, Φ1500mm×1450mm dryer 1set, Φ400mm×1450mm touch roll 1set, Rubber hardness HSD 90℃±2

E. Winding machine part: Winding paper can: 1 set In it through cooling water, which is for paper temperature reduction, so it is easy to rewind; Winding roll: two, Ø159mm,made from 10mm roll cart, axle head is 45# steel

F. Driving & control part: Motors with AC frequency convertor & adjustable speed, processing transmission. All Digital Close-Loop control system.

G. Foundation part: From cylinder part to the driven side of the winding machine and the foundation plate of operation side.

| Raw material | Straw |

| Output paper | Cultural paper |

| Net paper width | 1200mm |

| Paper weight | 45-80g/㎡ |

| Capacity | 5T/D |

| Rail gauge | 1800mm |

| Cylinder mould width | 1550mm |

| Drive | AC Frequency conversion, section drive |

◆ The Main Structure

A. Cylinder part: TwoΦ1250mm×1450mm cylinder moulds, TwoΦ350mm×1500mm couch rolls, Rubber hardness HSD

B. Compression part: One Φ450mm×1450mm stone roll, One Φ400mm×1450mm rubber roll, Rubber hardness HSD 90℃±2, Pneumatic loaded device

C. Dryer part: Φ2000mm×1450mm dryer 1set, Φ1500mm×1450mm dryer 1set, Φ400mm×1450mm touch roll 1set, Rubber hardness HSD 90℃±2

D. Calander part: Φ2000mm×1450mm dryer 1set, Φ1500mm×1450mm dryer 1set, Φ400mm×1450mm touch roll 1set, Rubber hardness HSD 90℃±2

E. Winding machine part: Winding paper can: 1 set In it through cooling water, which is for paper temperature reduction, so it is easy to rewind; Winding roll: two, Ø159mm,made from 10mm roll cart, axle head is 45# steel

F. Driving & control part: Motors with AC frequency convertor & adjustable speed, processing transmission. All Digital Close-Loop control system.

G. Foundation part: From cylinder part to the driven side of the winding machine and the foundation plate of operation side.

inquiry

Please fill in your procurement needs and contact information

English

English русский

русский  عربي

عربي  中文

中文