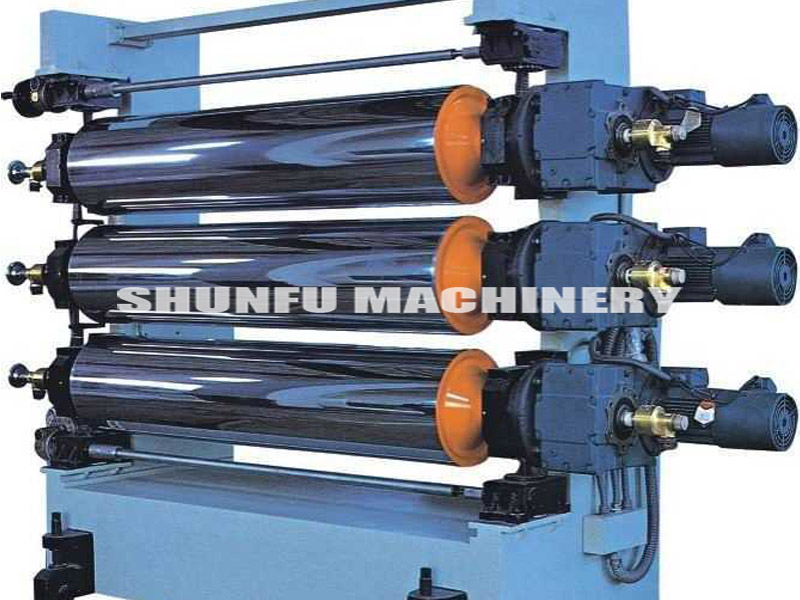

Calender Machine

- Application:Paper Industry

- Power:100-200kw

- Voltage:380v

- Certification:ISO9001;CE

- Warranty:1 year

We are here to help:Easy ways to get the answers you need.

- Culture paper machine

-

- 2400mm Type Fourdrinier Multi-Dryer Newspaper Machine

- 2800mm Daily Capacity 40 Tons Fourdriner Culture Paper Machine

- 1575 Fourdrinier Cultural Paper Machine

- 1092 Type Capacity 3-4tons Writing Paper Machine

- 6-8tons culture paper machine

- 1092mm Fourdrinier Paper Making Machine

- 1092 Type Capacity 5tons Culture Paper Machine

- 787mm Type Culture Paper Machine

- 1575mm type culture paper making machine

- Specialty paper machine

-

- 1600A Model Kraft Paper Slitting Machine

- 1760mm Multi-Dryer Five Cylinder Mould Grey Cardboard Machine

- 1092mm Multi-Dryer Five Cylinder Mould Grey Cardboard Machine

- 2100mm Multi-Dryer Five Cylinder Mould Paperboard Machine

- 4 Heads CNC Spiral Paper Tube Machine

- 2 Heads CNC Spiral Paper Tube Machine

- Capacity 5-8 Per Day Paperboard Machine

HOT PRODUCT

Describe

◆ Product Description

| Model | XY-3L 630 | XY-3L 1120A XY-L 1120A XY-3l1120A |

XY-3L 1400 | XY-3L 1200 XY-3L 1500 |

XY-3L 1730 |

| Roll diameter(mm | 230 | 360 | 400 | 450 | 610 |

| Roll working length(mm) | 630 | 1120 | 1400 | 1200(1500) | 1730 |

| Roll speed ratio | 1:1:1 1:1.42:1 |

1:1:1 0.733:1:1 0.733:1:0.733 |

1:1:1 1:1.383:1.383 1:1.383:1 |

1:1:1 1:1.5:1 |

1:1:1 1:1.4:1 |

| Middle roll linear speed(m/min) | 7.97 | 7.0-21.06 | 8.8-26.39 | 8.36-25.08 | 5.4-54 |

| Adjusting nip range(mm) | 0-7 | 0-10 | 0-10 | 0-6 | 0-20 |

| Min.Calendering product thickness | 0.2 | 0.2 | 0.2 | 0.15 | 0.15 |

| Calendering product width(mm) | 100-500 | 500-920 | 1200 | 1100(1400) | 1500 |

| Motor power (kw) | 7.5 | 40/13.3 | 55/18.3 | 75/25 | 132 |

| Weight (kg) | ∼4200 | ∼12750 | ∼26000 | ∼27000 | ∼52000 |

◆ Machine Structure

Bottom roll: Φ400×1900×1800/one piece

Middle roll: Φ250×1900×1800/ one pieces

Upper roll: Φ300×1900×1800/one pieces

<PS>:Material: chill cast steel, surface grinding

◆ Operation Flow

Calender work usually involves a continuous roll. Print from the feed transport to the pressure of light between the pressing roller and a pressure roller, the temperature and pressure under the effect of coating surface is attached to the pressure of light pressure light. After the calendering, the cooling layer is cooled to form a bright surface layer.

inquiry

Please fill in your procurement needs and contact information

Related products

English

English русский

русский  عربي

عربي  中文

中文