2100mm Multi-Dryer Five Cylinder Mould Paperboard Machine

- Raw material:Waste paper

- Output paper:Board paper, card board

- Net paper width:2100mm

- Paper weight:320-500g/㎡

- Capacity:30-35T/D

We are here to help:Easy ways to get the answers you need.

- Culture paper machine

-

- 2400mm Type Fourdrinier Multi-Dryer Newspaper Machine

- 2800mm Daily Capacity 40 Tons Fourdriner Culture Paper Machine

- 1575 Fourdrinier Cultural Paper Machine

- 1092 Type Capacity 3-4tons Writing Paper Machine

- 6-8tons culture paper machine

- 1092mm Fourdrinier Paper Making Machine

- 1092 Type Capacity 5tons Culture Paper Machine

- 787mm Type Culture Paper Machine

- 1575mm type culture paper making machine

- Specialty paper machine

-

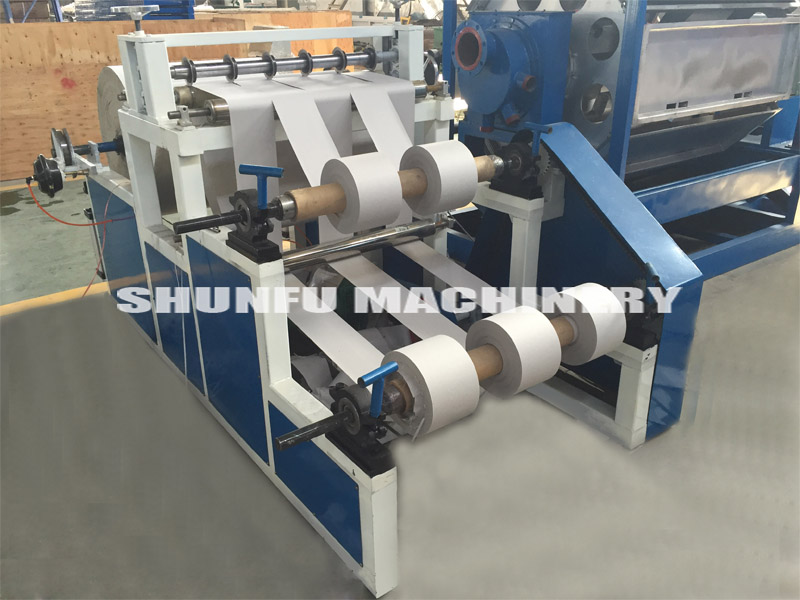

- 1600A Model Kraft Paper Slitting Machine

- 1760mm Multi-Dryer Five Cylinder Mould Grey Cardboard Machine

- 1092mm Multi-Dryer Five Cylinder Mould Grey Cardboard Machine

- 2100mm Multi-Dryer Five Cylinder Mould Paperboard Machine

- 4 Heads CNC Spiral Paper Tube Machine

- 2 Heads CNC Spiral Paper Tube Machine

- Capacity 5-8 Per Day Paperboard Machine

HOT PRODUCT

Describe

◆ Technical Parameter

|

Raw material |

Waste paper |

| Output paper | Board paper, card board |

| Net paper width | 2100mm |

| Paper weight | 320-500g/㎡ |

| Capacity | 30-35T/D |

| Rail gauge | 3000mm |

| Designed speed | 50m/min |

| Working speed | 30-35m/min |

| Density of wire | 0.5-0.8% |

| Paper dryness of wire part | 15-18% |

| Paper dryness of press part | 30-38% |

| Dryness of finish paper | 95% |

| Arrange mode | left and right hand machine |

| Drive | AC Frequency conversion, section drive |

Main device of paper machine: Five cylinder part, two pre-press(Φ500/450mm), Three main pressure(Φ700/650mm, Eighteen sets dryer (Ø1500mm12sets+ two roll calander+ Ø1500mm6sets)+ two roll calander +winding machine +rewinding machine.

◆ Technological Process

Raw material → Hydrapulper → Vibrating sieve → Horizontal mixer(crude pulp tank) → Pulp pump→ Refiner → Horizontal

mixer(ajust pulp tank) → Pulp pump → Centrifugal screen machine → Horizontal mixer(finished pulp tank) → Pulp

pump→ Steady pulp box → Enter cylinder mould box→ Forming paperboard → Enter hot pressure machine to drying

◆ Why choose us

1.Manufacture:

1)Keep the quality first;

2)make more products benefit to customers’need

2.Online/Sale service:

1)super and solid quality;

2)Fast and punctual delivery;

)Standard export package or as customers’ need.

3.After-sale service:

1)Assistance to build factory or your project;

2)Repairing and maintenance if any problem occur in the warranty.

3)Installation and clerks training;

4)Any feedback of machines can be told us, and we will try our best to support you.

4.Other cooperation service:

1)Technology knowledge share;

2)Factory building advising;

3)Business expansion advising

inquiry

Please fill in your procurement needs and contact information

English

English русский

русский  عربي

عربي  中文

中文